Process

WHAT IS STERILIZATION?

Sterile: Free from any living organisms.

Sterilization: Process of killing or removing microorganisms from a product to insure that it is sterile.

EO ADVANTAGES

- Highly effective against most microbes

- Highly diffusive

- Compatible with a wide variety of materials in devices and packaging

EO DISADVANTAGES

- Complex process

- Longer turn-around times

- BI Testing

- Residual dissipation

- Safety concerns

- Flammable

- Explosive

- OSHA concerns

- Carcinogen

- EPA concerns

- Emissions

USERS OF ETHYLENE OXIDE

- Anyone who supplies a product on which the presence of microorganisms could present a health risk.

- Manufacturers of any product that enters the body, except by ingestion:

- Medical Device Manufacturers

- Pharmaceutical Manufacturers (Both human & veterinary)

- Hospitals, Dentists, other health care facilities

- Some specialty food product manufacturers

EO PROCESSING STEPS

- Preconditioning/conditioning

- Exposure to RH and temperature

- Ensure uniformity of these conditions

- Sterilization cycle

- Exposure to EO gas

- Aeration

- Dissipation of remaining gases

DECISIVE PROCESS PARAMETERS

- Gas concentration >400mg/L

- Temperature ~100 – 140ºC

- Relative humidity ~35 – 80%

- Exposure (dwell) time 2 – 10 hours

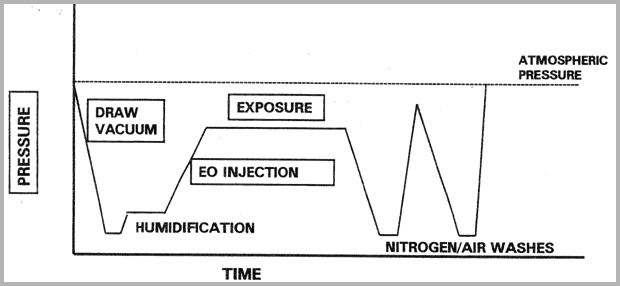

DEEP VACUUM CYCLE

SHALLOW VACUUM CYCLE

FACTORS AFFECTING CYCLE SUCCESS

- Bioburden

- Product/package properties

- Loading configuration

- Cycle parameters

DETERMINE THE STANDARD

- AMI/ISO 11135-01 4ed

“Sterilization of health care products – Ethylene oxide - Part 1: Requirements for the development, validation and routine control of a sterilization process for medical devices”

- Europe – EN 550

EO VALIDATION OVERVIEW

- Process development

- Product compatibility

- Commissioning

- PQ – Physical

- PQ – Microbiological

- Certification

- Revalidation

PROCESS CONTROL

- Must assure that validated process parameters are met

- Temperature

- RH

- Gas concentration

- Biological indicators are used to demonstrate lethality

- Microprocessors are used to control process

RELEASE MECHANISMS

- Documentation showing that processing specification are met

- Successful results of tests

- Sterility of BI

- EO residues

- Packaging

- Pyrogens

PARAMETRIC RELEASE

- BIs not used in release

- Validation more involved

- Routine control more rigorous

- AAMI TIR20:2001 “Parametric release for ethylene oxide sterilization”

PRODUCT COMPATIBILITY

- Post sterilization testing for

- Device functionality

- Package integrity and strength

- Residue dissipation rates

- Impact of re-sterilization

COMMISSIONING

- Equipment specifications/diAhmedabadm

- Calibration records

- Profiles for

- Preconditioning (temp. and RH)

- Aeration rooms (temp.)

- Empty chamber temperature distribution

PQ – PHYSICAL

- Profiles within loaded preconditioning and aeration areas

- Loaded chamber temperature distribution studies

- DiAhmedabadms showing load configuration, thermocouple and BI placement

PQ – MICROBIOLOGICAL

- Records of performance runs (sub-lethal, half, and full cycles)

- DiAhmedabadms of load configuration with BI and thermocouple placement

- BI test result

- Sterility test result of product

- B/F testing

INITIATING A VALIDATION

- Determine the standard

- Insure appropriate packaging

- Determine worst case load

- Determine challenge device

- Internal

- Process challenge device (PCD)

- Select Validation Method

- BI release

- Parametric

CHALLENGE DEVICES

- Internal Challenge Device (ICD)

- Most difficult to sterilize devices seeded with a BI in the most difficult to sterilize location

- PCD

- An external BI test pack that replaces the internal challenge device

- Should be an equal or more difficult challenge to the process than the ICD

- Developed using comparative resistance studies

PARAMETRIC RELEASE

- Benefits

- Faster TAT

- Useful if extended aeration not required

- Considerations

- More complicated validation

- Minimum of 6 or 7 sub lethal cycles

- Direct measurement of EO, RH and temp.

- Load configuration becomes more critical

BI RELEASE

- BI Overkill (most common)

- Demonstrate 10-6 SAL

- Assume bioburden has lower population & resistance than BI

- Need a > 12 Spore Log Reduction (SPL) of BI

- Combined BI/Bioburden

- Absolute Bioburden (rarely used)

BIOBURDEN TESTING

- Test 10 samples randomly selected

- Determine recovery factor – validation

- If bioburden >100, comparative resistance study required

- If bioburden <100, you are OK

SAMPLE PLACEMENT

- Protocol must detail the number and location of all samples in load

- BI’s

- Product sterility (if applicable)

- ETO residuals

- Product functionality

- Package integrity

- LAL

VALIDATION CYCLES

- Fractional cycles

- Half cycles

- Full cycles

FRACTIONAL CYCLE

- Must be run when bioburden >100 and no comparative resistance studies are performed

- Desired cycle time must results in some positive BI and sterile product in sterility tests

- A minimum of 20 product sterility samples (10 TSB, 10 FTM)

- Product sterility samples must be placed adjacent to BI

HALF CYCLES

- Three half cycles must be run in production chamber with a gas dwell time half the full cycle dwell time

- The following must be placed in load

- Temperature and humidity sensors

- Internal BI

- External BI (optional)

- Product sterility samples if comparative resistance studies not done or inconclusive

FULL CYCLE

- A minimum of one full cycle is required for the Micro PQ

- Three cycles are required to meet residual requirements

- The following samples are included

- EO residual

- Product functionality

- Packaging integrity

- External BI (routine release BI)

- LAL

EO RESIDUAL TESTING

- 1 - 3 samples of each type should be tested at a minimum of 3 time intervals from processing (Ex. 1, 3, & 5 days)

- This must be done after 3 full cycles

- Testing for EO and ECH

- Samples must be shipped frozen

ACCEPTANCE CRITERIA

- Bioburden must be in control

- Product sterility all neg after half cycles

- Acceptable B&F test

- BI Testing

- Fractional cycle - some should grow

- Half cycle - all negative

- Full cycle - all negative

ANSI/AAMI/ISO Standards Ethylene Oxide Sterilization

- Medical Devices – Validation and routine control of EO sterilization (ANSI/AAMI/ISO 11135: 1994)

- Contract Sterilization for EO (AAMI TIR 14:1997)

- Process development and performance qualification for ethylene oxide sterilization -microbiological aspects (AAMI TIR 16:2000)

- Parametric release for EO sterilization (TIR 20)

- Biological Evaluation of Medical Devices-Part 7: EO sterilization residuals (10993-7)

REFERENCES

- AAMI/ISO 11135-01 4ed. Sterilization of health care products- Ethylene oxide- Part 1: requirements for the development, validation and routine control of a sterilization process from medical devices

- AAMI TIR No. 16:2000, Process development and performance qualification for ethylene oxide sterilization – Microbiological aspects

- AAMI TIR No. 29:2001, Parametric release for ethylene oxide sterilization

- AAMI TIR 28:2001, Product adoption and process equivalency for ethylene oxide sterilization